Specs/CAD

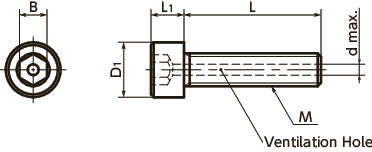

Unit : mm

| Part Number | M (Coarse) Nominal of Thread |

Pitch | L | D1 | L1 | B | d max. |

Qty per Pack | Mass (g)*1 |

Price (USD) |

CAD Download |

QTY (Pack) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SVSS-M6-8-PC | M6 | 1 | 8 | 10 | 6 | 5 | 2 | 10 | 4.3 | 47.79 | CAD | Cart |

| SVSS-M6-10-PC | M6 | 1 | 10 | 10 | 6 | 5 | 2 | 10 | 4.7 | 49.94 | CAD | Cart |

| SVSS-M6-12-PC | M6 | 1 | 12 | 10 | 6 | 5 | 2 | 10 | 5.1 | 50.90 | CAD | Cart |

| SVSS-M6-16-PC | M6 | 1 | 16 | 10 | 6 | 5 | 2 | 10 | 5.8 | 55.67 | CAD | Cart |

| SVSS-M6-20-PC | M6 | 1 | 20 | 10 | 6 | 5 | 2 | 10 | 6.5 | 63.85 | CAD | Cart |

| SVSS-M6-25-PC | M6 | 1 | 25 | 10 | 6 | 5 | 2 | 10 | 7.6 | 66.97 | CAD | Cart |

| SVSS-M6-30-PC | M6 | 1 | 30 | 10 | 6 | 5 | 2 | 10 | 8.3 | 70.99 | CAD | Cart |

| SVSS-M6-35-PC | M6 | 1 | 35 | 10 | 6 | 5 | 2 | 10 | 9.9 | 79.31 | CAD | Cart |

| SVSS-M6-40-PC | M6 | 1 | 40 | 10 | 6 | 5 | 2 | 10 | 11 | 87.25 | CAD | Cart |

| SVSS-M6-45-PC | M6 | 1 | 45 | 10 | 6 | 5 | 2 | 10 | 12 | 91.09 | CAD | Cart |

| SVSS-M6-50-PC | M6 | 1 | 50 | 10 | 6 | 5 | 2 | 10 | 13 | 102.84 | CAD | Cart |

*1: Quantity per pack for SVSS-M4×30-PC and SVSS-M4×35-PC is 10 pieces. Quantity per pack for SVSS-M8×60-PC is 5 pieces.

Nabeya Bi-tech Kaisha

Customer Service

Please enter questions about customization and other product-related inquiries here.

Find the inquiry form hereRelated Services

Material/Finish

| SVSS-PC | |

|---|---|

| Main Body | SUSXM7 (S.S. grade:A2) Chemical Polish |

| Strength Class | A2-70 |

Application

Vacuum devices, vacuum chambers, FPD production equipment, semiconductor devices, and electron microscopesCharacteristics

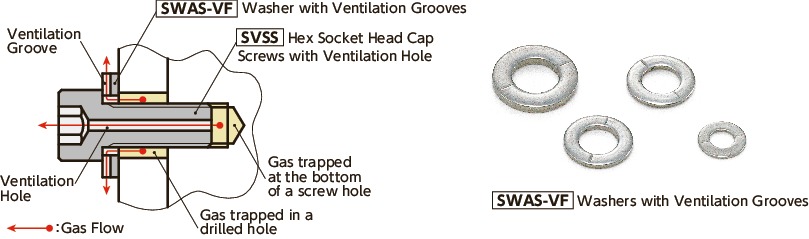

- The ventilation hole easily releases gas trapped in the screw holes of equipment and machines, and supports vacuum drawing of vacuum devices.

- Cleanroom wash and cleanroom packing are completed.⇒Cleanroom Wash / Cleanroom Packing Service

- SVSS-PChas an improved surface coarseness by chemical polishing. Outgas quantity is extremely low. Suitable for the use under medium vacuum environments.

- Ventilation holes are made using a method that has little effect on metal structure. The occurrence of outgas under vacuum environment and brittle fracture during usage are suppressed respectively.

Usage Example

Gas trapped at the bottom of a screw hole is released through SVSS, and gas trapped in a drilled hole is released through SWAS-VF(SWAS-VFSWAS-VF-PC).