Date Published:Sep. 11. 2017 Date Updated:Dec. 28. 2022

What are clamp levers? Here we explain the characteristics and usage methods that help streamline screw tightening!

➡To [Description of Mechanical Components for Engineers]

What are clamp levers?

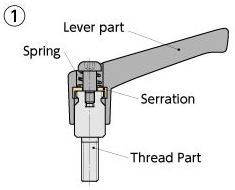

Clamp levers are mechanical components which allow efficient tightening and loosening of screws by turning the lever without the use of tools. Their best feature is the ability to work in tight spaces: just pull up the lever to release the threaded serration engagement (This will stop the screw from turning even if the lever is rotated).

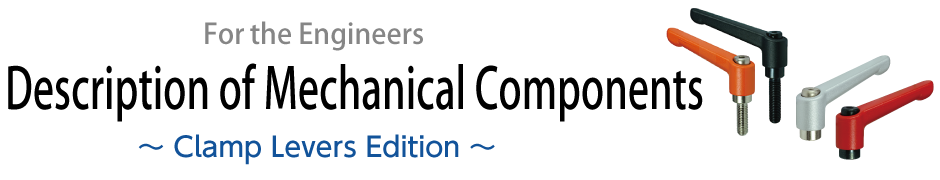

Clamp Lever Structure

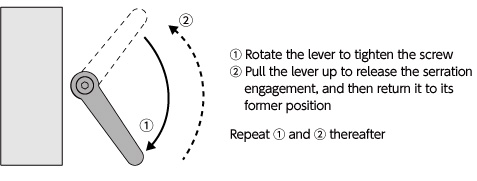

① Since the lever and threaded serration are normally engaged, turning the lever causes the screw to rotate simultaneously.

② Pulling up the lever releases the threaded serration engagement (the screw will stop turning when the lever is rotated).

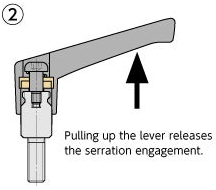

③ Releasing the lever allows it to return automatically to lever and threaded serration engagement position due to the built-in spring force.

Only takes a minute to understand! How to Use Clamp Levers.

Using the features of the clamp lever ・・・

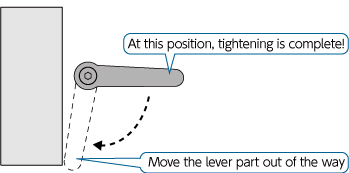

Screws can be tightened in places where the lever cannot rotate 360°.

After screw tightening, the lever position can be moved aside to keep it out of the way.

Advantages of using clamp levers

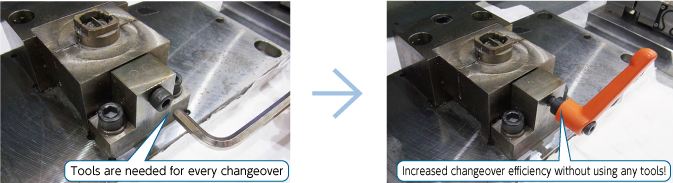

Higher work efficiency without tools

The use of clamp levers increases work efficiency, since tools such as wrenches and spanners used on screws are no longer required. Clamp levers are efficient in places where screws are frequently handled, such as equipment changeover.

Space-saving for equipment

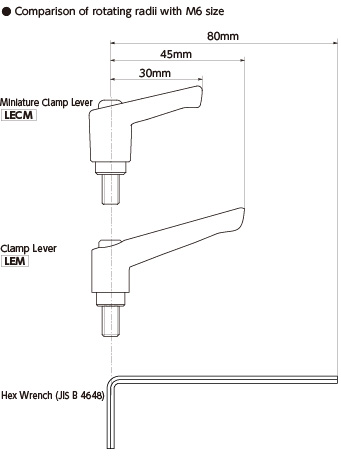

With a smaller rotating radius than normal tools, screw operation space can be reduced.

The NBK miniature clamp lever series, with an even smaller rotating radius, provides optimum space-saving for equipment.

>>Miniature Clamp Lever Series

Easily standardize work

NBK clamp levers are available in a wide variety of colors. This contributes to work standardization by drawing attention to the area of operation, clarifying operation procedures with different colors, and so on.

Examples of clamp lever applications

Shaft position adjustment

Workpiece fixing

Types and Features of Clamp Levers

An abundant lineup is available from standard to unique products. NBK will provide the clamp levers that meet your particular requirements.

Material Types

Lever materials include zinc die-cast, stainless steel, and plastic; materials for the threaded part include steel and stainless steel.

Material Types and Features

| Material Types and Features | Characteristics |

|---|---|

| Zinc Die Cast | High Strength |

| Stainless Steel | High Corrosion Resistant |

| Plastic | Low CostLightweight |

| Thread Part Material | Characteristics |

|---|---|

| Steel | High StrengthLow Cost |

| Stainless Steel | High Corrosion Resistant |

Screw Types

The two basic screw types are male and female.

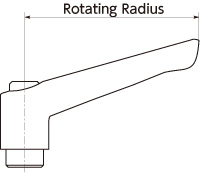

Rotating Radius Types

The two types of rotating radiuses are "Standard" and "Compact". The rotating radius for the "Standard" type varies, depending on the screw size, over a range from 45 mm to 108 mm. The rotating radius for the "Compact" type is 30 mm for all sizes.

Function Types

Along with standard clamp levers, NBK also offers clamp levers with unique functions as an option.

With Push Button

The push button allows easy application of force when pulling up the lever, making operation easier. The push button shape has no holes, helping prevent the accumulation of dust and dirt.

Universal Design

This clamp lever design incorporates the 7 principles of Universal Design. >>About Universal Design

Lineup by Features

| Material | Screw Type | Rotating Radius | Characteristics | |||

|---|---|---|---|---|---|---|

| Lever Material | Thread Material | Standard | With Push Button | Universal Design |

||

| Plastic | Steel | Male Screw | Standard | LEM

LEME |

LEM-C | LUDM |

| Compact | LECM | LECM-C | ||||

| Female Screw | Standard | LEF

LEFE |

LEF-C | LUDF | ||

| Compact | LECF | LECF-C | ||||

| Stainless Steel | Male Screw | Standard | LEMS | LEMS-C | LUDMS | |

| Compact | LECMS | LECMS-C | ||||

| Female Screw | Standard | LEFS | LEFS-C | LUDFS | ||

| Compact | LECFS | LECFS-C | ||||

Product Finder

Our convenient "Product Finder" enables rapid searching for your desired products.

Additional Service

To make NBK products compatible with a wider range of applications, various additional standard modifications are available. Orders of one piece or more can be processed for quick delivery.

Laser Engraving

Various marks and letters are laser-engraved on Clamp Levers. This is a service to make the NBK products even easier to use in terms of functionality by engraving marks such as OPEN, CLOSE, and arrows.

Length Adjustment

Screws can be cut to your desired length in 1mm increments.

Screw Combination

Levers/clamp levers’ female screws are bonded with screws by anaerobic adhesive agent and fixed with pins.

Cleanroom Services

We can wash and pack your products in a cleanroom. This is suggested for products used in FPD production devices, semiconductor manufacturing devices, medical equipment, food and beverage machinery and even products that will be used in cleanrooms.

Special Products

Come to us for production of non-standard clamp levers as well, including lever part color changes and special shapes.